Technology

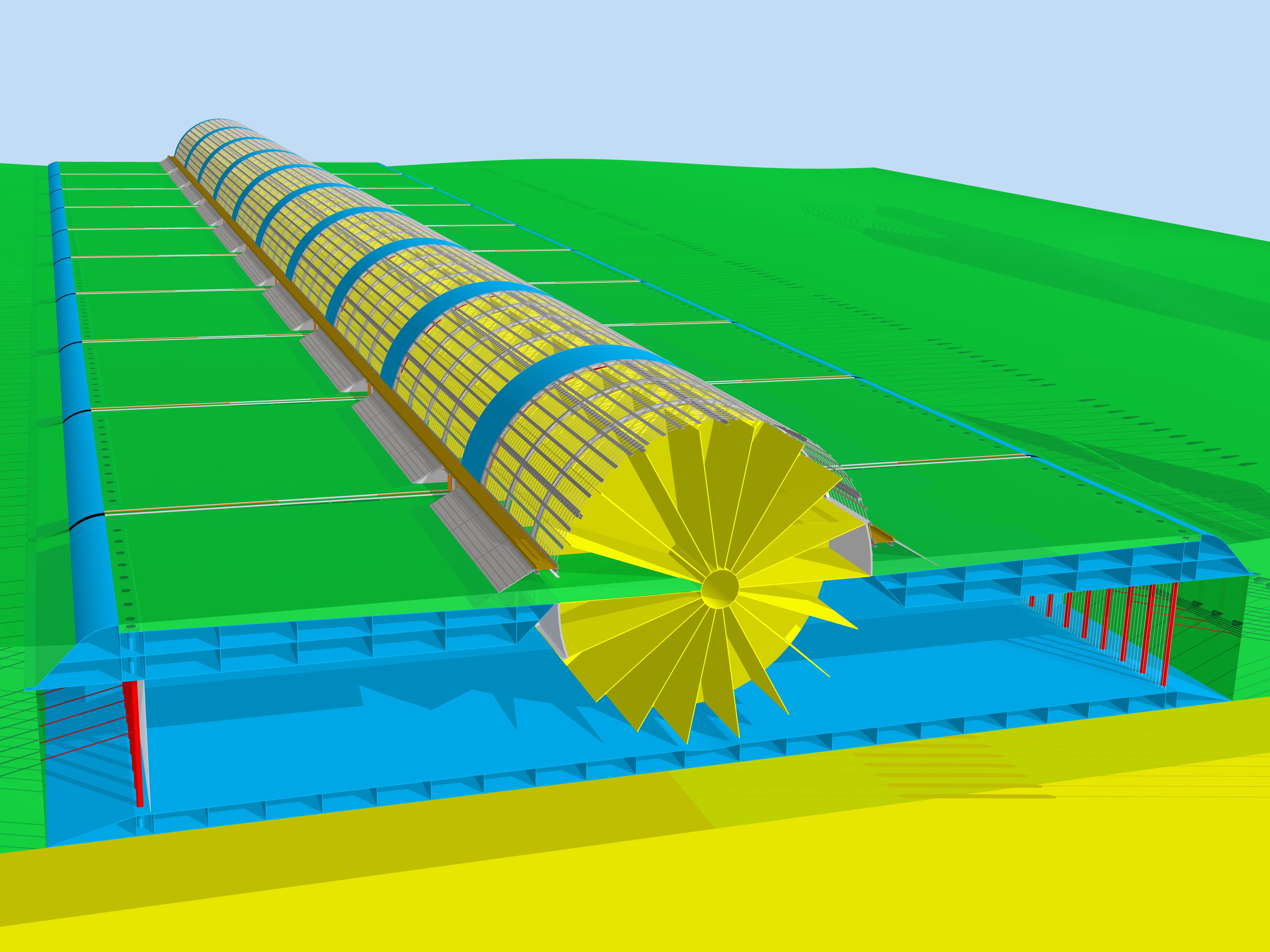

The hydrokinetic device (turbine) is a floating structure with a single horizontal axis rotor that converts the kinetic energy of tidal streams into electricity at an efficiency of 40%. Applying tidal fence theory, turbine tidal energy conversion efficiency could exceed 80%.

Through the use of an angled deflector, waves flow over the structure (overtopping) into an elevated reservoir to capture the potential energy of the waves. The same rotor is then used to convert the kinetic energy of the tidal stream and potential energy of the waves into electricity. This approach significantly increases the accessible energy density for the selected turbine location and delivers transformational project economics.

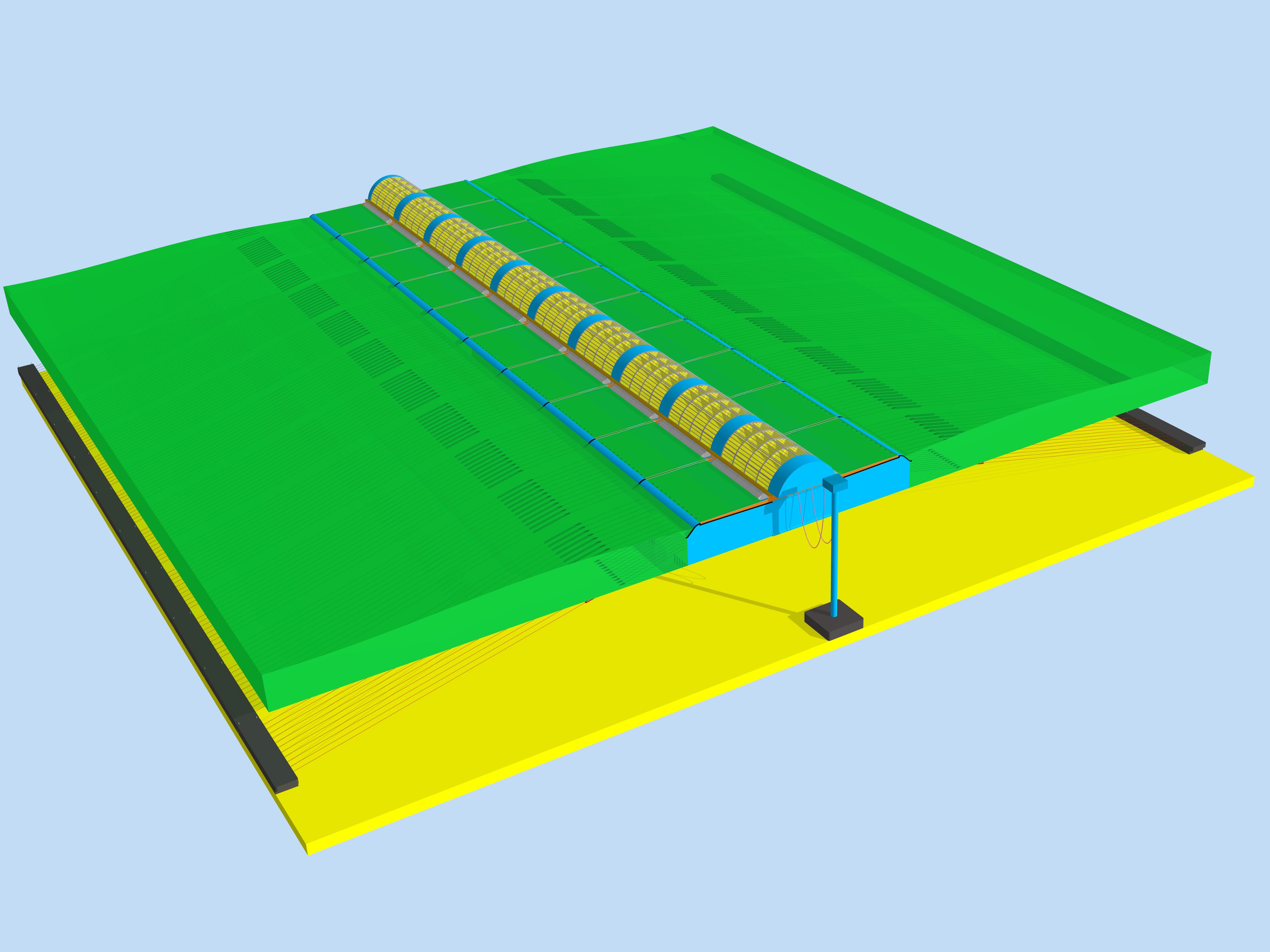

The turbine is a semi-submersible floating structure, which minimises wave impact forces and makes it visually unobtrusive to the local population. The turbine design is also environmentally friendly to the local fish and marine mammal populations as the maximum rotor tip velocity is below 3 m/s**. It is also visually unobtrusive with a visual impact similar to a yacht sail, extending approximately 10 metres above sea level.

Our floating design approach has many advantages. It facilitates routine maintenance and defouling activities by eliminating the need for specialist lifting equipment or complex engineering designs to recover the turbine from the sea bed. It also negates the need for expensive and voltage limiting subsea inductive couplings.

All routine maintenance and repair activities, including anchor cable replacement, can be completed on site with the use of a service vessel incorporating a 10 tonne crane. For steel turbines, dry-dock visits will be required every 10 years for hull inspections, whereas concrete turbines can remain at sea indefinately.

The prototype has a rating of 1.0 MW, however larger structures are considered quite feasible as the technology for the construction of large floating structures is well understood in the oil & gas and civil engineering industries.

** Hydropower good practise guidelines - UK Environmental Agency Dec 2012.

Isometric view of ten turbines.

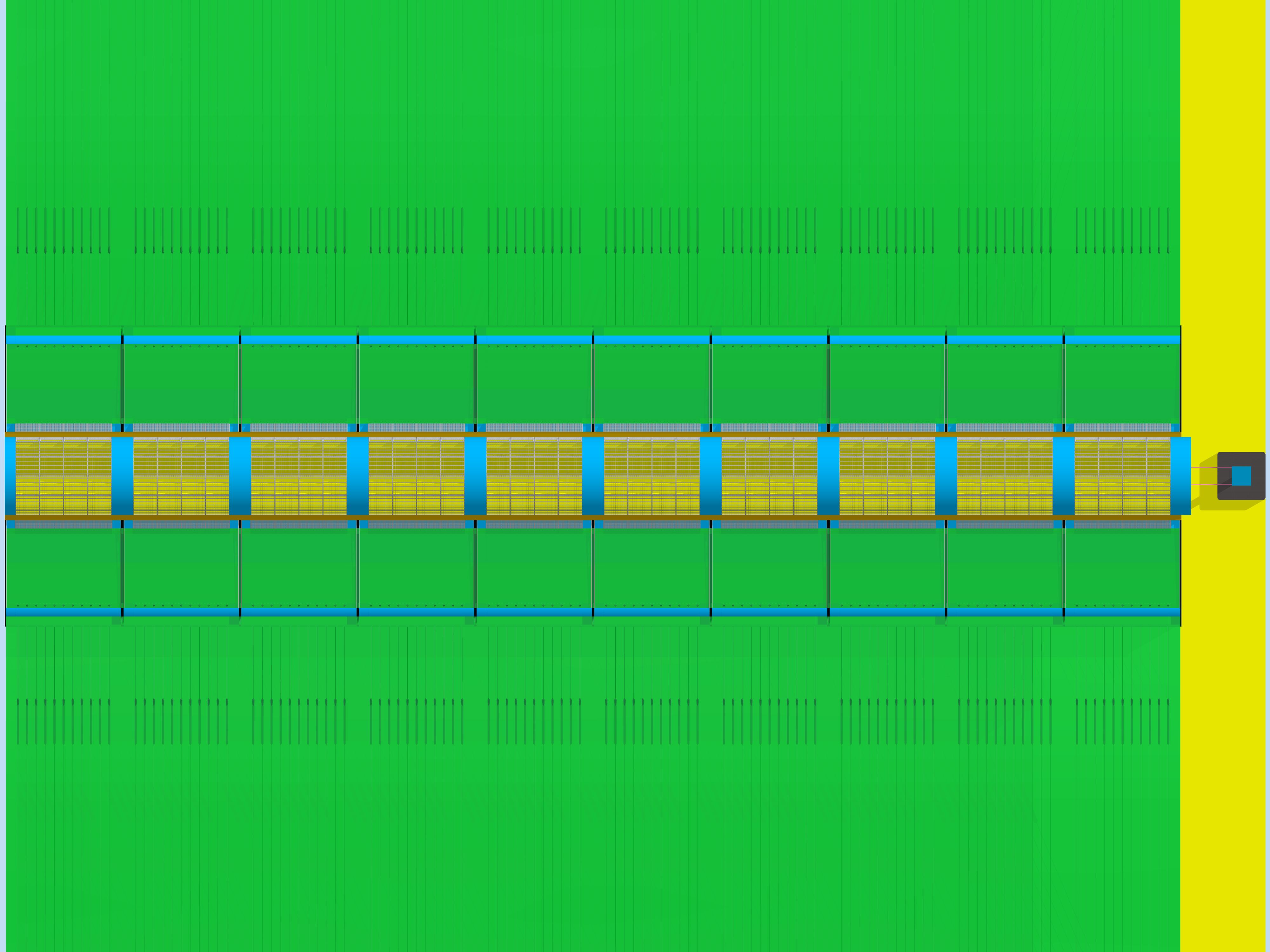

Plan view of turbine array.