Power Take-off And Electrical Export System

Electrical Power Take-off

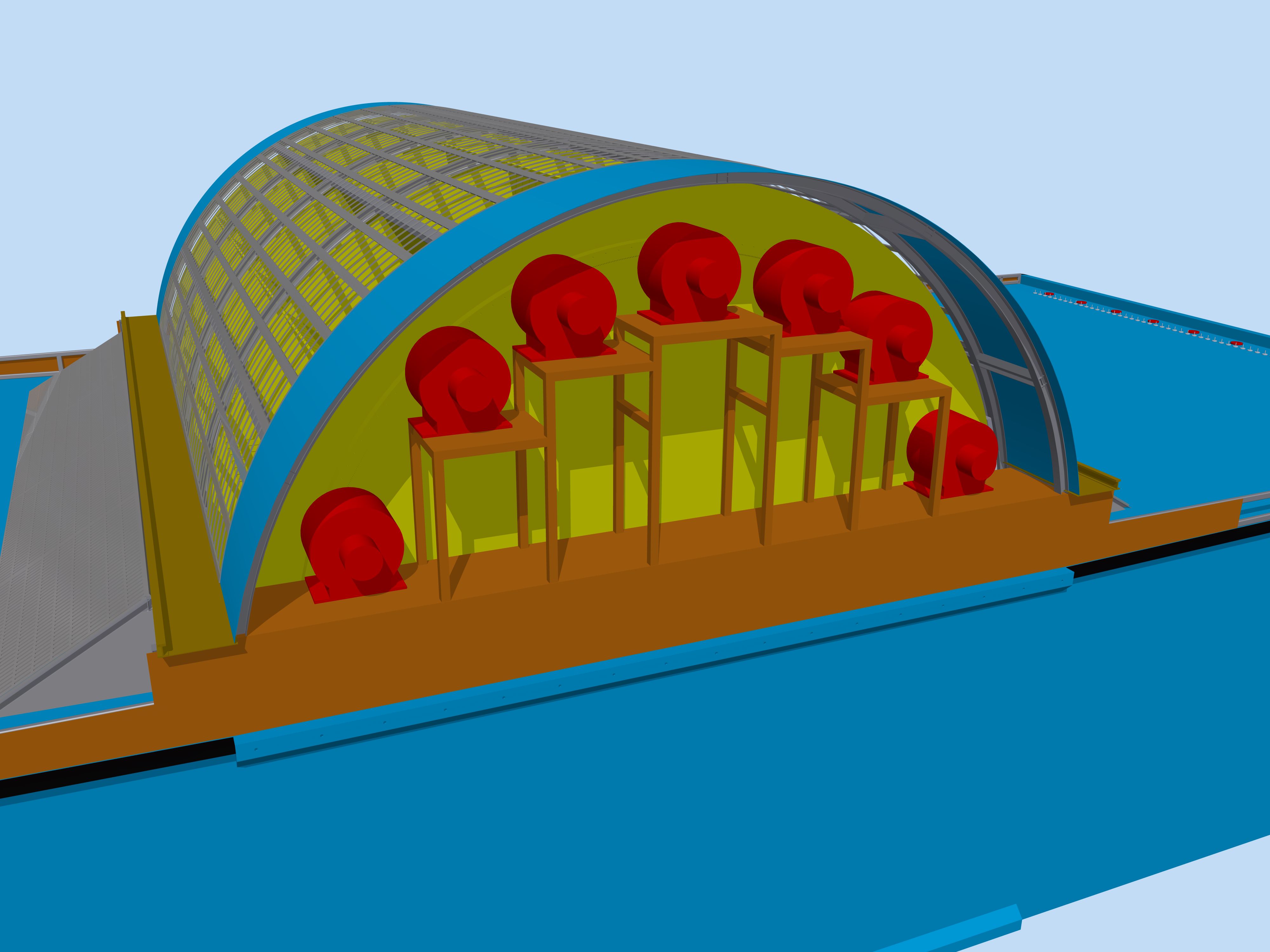

The Pliosaur Energy turbine operates at a very low speed of approximately 1-2 rpm and hence delivers the mechanical energy at a very high torque. This is a very difficult and costly engineering challenge for many turbine developers to solve as engineering design space for subsea turbines is very limited. Our solution, which is very cost effective and removes ₤million's from the development budget, is a large diameter ring gear which is attached to the side of the rotor. This ring gear then drives a spur gear which now operates at 30 rpm, which is similar to a wind turbine. The end of the spur gear shaft is machined to mate with the splines of wind turbine gearbox and alternator assembly. This technology can then be used to generate electricity with minimal development and capex cost. It also solves the Pliosaur Energy rotor brake problem as each wind turbine gearbox already has a disc brake fitted as standard.

A schematic of the Pliosaur Energy turbine fitted with seven drivetrains.

Electrical Export

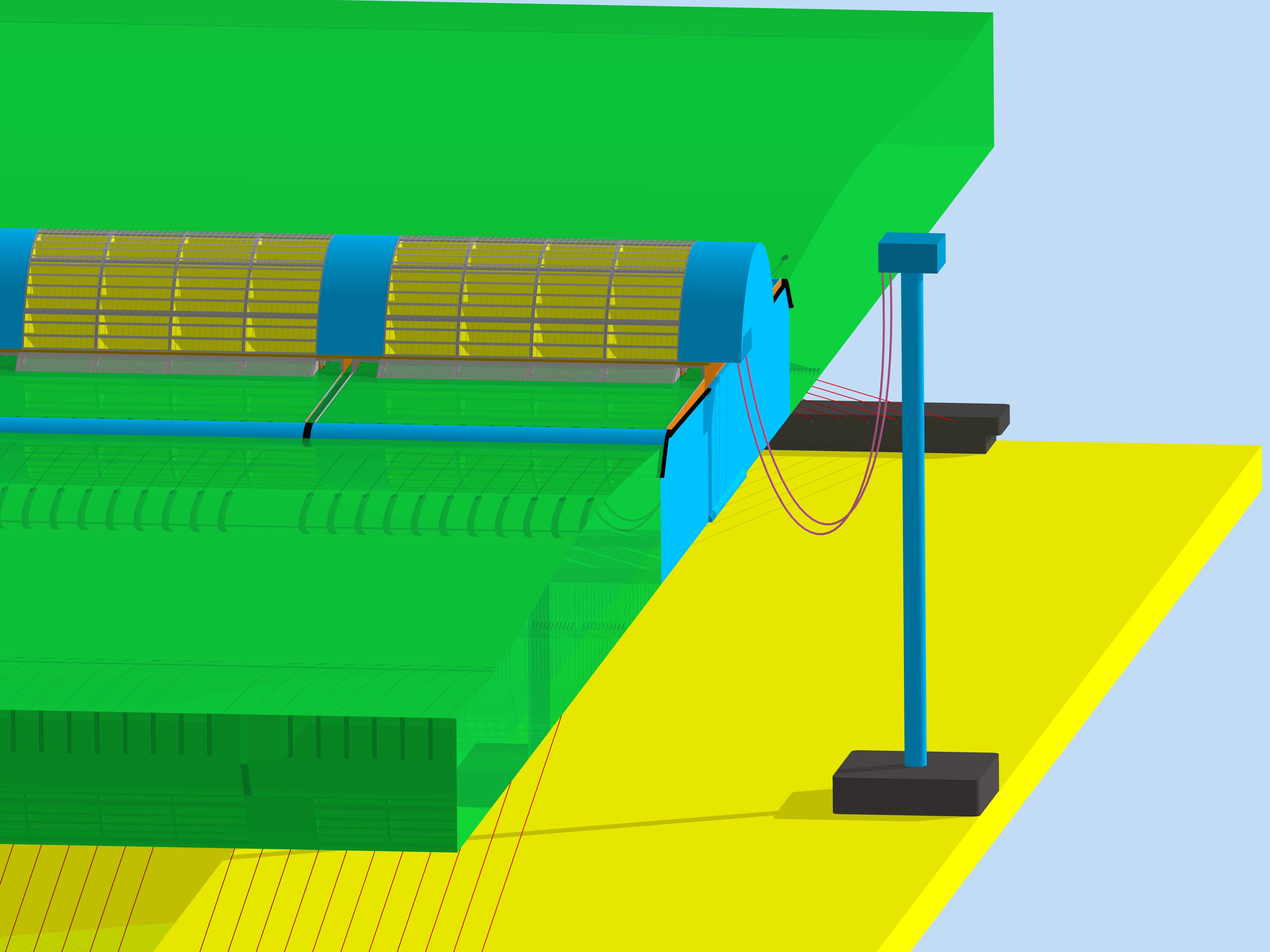

Our proprietary technology eliminates the need for the excavation of intra-turbine power cables thereby reducing project capex and minimising the environmental impact of our turbines. Instead they are run between the turbines as the turbines are configured in a line. This approach brings with it many advantages as it eliminates the risk from wave induced seabed chaffing. Furthermore, it eliminates the need for voltage limiting inductive couplings for each turbine.

The export power cable is connected to the first turbine in the line, however as the turbines are taut moored any electrical cable fatigue is minimised. This export power cable is then suspended between the turbine and an adjacent caisson with switchroom mounted at the top. Given the predicted mean time between failure (MTBF) of the copper conductors in the export power cable is anticipated to be 1-2 years, this approach will minimise the project life operations cost considerably as no costly subsea interventions are required.

A Pliosaur Energy (PE) array can be installed underneath a wind turbine array with a minor modification of one wind turbine caisson to allow interconnection of the PE export power cable. The export power cable may then be spliced into an uprated wind turbine export power cable or run along side the wind turbine export cable array to the local switch room. There are many benefits with this approach not least improved utilisation of the wind turbine array export power cable infrastructure and a more reliable power supply to the national grid. Repair of the PE export power cable would be required, as outlined above, every 1-2 years.

The only seabed intervention required is the excavation of the export power cable to shore. With a minimum turbine water depth requirement of 10 metres, and its unobtrusive design only extending approximately 10 metres above sea level, it is anticipated that inshore locations may become accessible. The outcome from this approach is a shorter electrical tie-in cable to shore thereby minimising the potential environmental impact upon the benthic community and improved project economics.